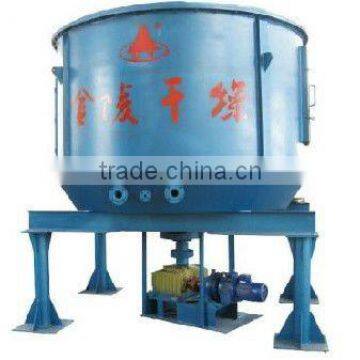

PGC Series Vacuum Dryer

- Shanghai

- T/T

You May Like

Product Details

| Type | Rotary Drying Equipment | Brand Name | Changjin | |

| Model Number | PGC |

Product Description

Specifications

PGC vacuum dryer has simple regulation and control,low energy consumption and high drying efficiency.It is our patent.PGC Series Vacuum Dryer

Principle

Wet materials are fed continuously to the first drying layer on the top of dryer. Materials will be turned and stirred by rakes when the rake arm rotates and flow through the surface of drying plate along the exponential helical line. On the small drying plate, materials will be moved to its outer edge and drop down to the outer edge of the large drying plate underneath, then will be moved inward and drop down from its central hole to the small drying plate on the next layer. Both small and large drying plates are arranged alternately so as materials can go through the whole drier continuously. The heating medium, which could be in forms of saturated steam, hot water or heat conducting oil, will be led into hollow drying plates from one port to the other port of drier. Dried material will drop from the last layer of drying plate to the bottom layer of the shell body, and will be moved by rakes to discharging port. The moisture will be removed from the moist discharging port on top of cover, or sucked out by the vacuum pump on the top cover for vacuum-type plate drier. The dried materials discharged from the bottom layer can be packed directly. Drying capability could be raised up if equipped with supplementary devices such as fin drier, condenser, bag filter, exhaust fan etc.

Features

1. Easy in regulation and control, strong adaptability.

Regulate thickness of material, speed of main shaft, number of rake arm, style of rakes and size of rakes to make drying process be optimal.

Each layer of drying plate can be led thermal or cold media individually to heat or cool materials, make temperature control accurately and easily.

Dwelling time of materials can be accurately adjusted.

Single flowing direction of materials without return flowing and mixing, even drying and stable quality, don’t need re-mixing.

2. Easy and simple operation

Start and stop of drier is quite simple.

After materials are stopped feeding and conveying, they can be easily exhausted out of dryer by rakes.

Cleaning and observation can be carried inside the equipment through large-scale viewing window.

3. Low energy consumption

Thin layer of materials, low speed of principle axis, small power and energy needed for material conveying system.

Dry by conducting heat so it has high heating efficiency and low energy consumption.

4. Good operation environment, solvent can be retrieved and dust powder discharge can meet requirement

Normal pressure style: as low speed of air flow inside the equipment and moisture being high in upper part and low in bottom part, dust powder couldn’t float to the top of the equipment, so there is almost no dust powder discharged in tail gas from the moist discharge port on the top.

5. Drying efficiency is high

The fixed disk is jacket in design. It can use liquid or steam as heat transfer medium to carry out heating or cooling. Material will drop from upper disk layer to lower disk layer as waterfall. It speeds up the drying or cooling rate. (If heat resource is steam, please indicate in contract.)

Applications

It is especially for drying and cooling powder materials like medicine, agriculture medicine, chemical industry, foodstuff, feedstuff and so on.

Organic chemical industry: Polyvinyl chloride, teflon resin, fumaric acid, anthraquinone, nitroanthraquinone, amino phenol, melamine, cyanogen uric acid, amino benzene xanthognic acid, antioxidant 168, color phenol AS, stearate, aniline, nitrophenylamine, double pentaerythritol, chlorination paraffin wax, calcium formiate, three ethylene diamidogen, benzene sulfinic acid sodium, benzene.m. dicarboxylic acid, dimethyl ester pentathionic acid sodium, thiourea, oil soluble aniline black dyestuffs, erie black dye and so on organic industrial chemicals and intermediate.

Inorganic chemical industry: Light quality calcium carbonate, active calcium carbonate, nanometer level superfine calcium carbonate, magnesium carbonate, aluminum hydroxide, white carbon black, strontium carbonate, barium carbonate, carbonic acid armor, lithopone, insurance powder, potassium sulfate, microballoons catalyst, magnesium hydroxide, cupric sulfate, nickel sulfate, nickel sour ammonium, sodium molybdate, sodium chloride, potassium chloride, calcium chloride, sodium fluoride, cryolite, oxidized iron oxide red, lithium hydroxide, nickelous hydroxide, zirconium hydroxide, calcium carbonate, sulfur and so on.

Medicine, food: Ammonia animal pen penicillin, Deng Yan, laevo-rotatory benzene glycine and intermediate, spore ammonia sai, spore three qin, An Naijin, west onamot for bulk drugs and medicine intermediate and so on Ding, Vitamin b, Vitamin c, for medicinal purposes leaning magnesium silicate, caffeine, tea, flowered extraction, gingko leaf, chocolate powder, starch, corn embryo tooth bud.

Feed, fertilizer: The potassium carbonate, the biological potassium fertilizer, the protein feed, the feed use the aureomycin, the bran, the distiller's grain, the grain, the weed killer, the cellulose, the feed calcium hydrogen phosphate and so on.

PGC vacuum dryer

Description

Feeding material into vacuum plate drier, because boiling point of material will fall under the state of vacuum and along with the rake turning over continuously, the surface of material will be changed continuously. Therefore it speeds up drying rate greatly. The wet air will be drew out by vacuum pump. This equipment is mainly used for drying heat sensitive material, toxic material and the material that easy to oxidize or needs to recover solvent.

Features

1. Under the state of vacuum, the machine can keep material to feed and discharge continuously.

2. Closed operation, it is particularly suitable for drying material that has toxicity or easy to oxidize.

3. It is very convenient to recover organic solvent in wet gas.

4. Low energy consumption, high efficiency, safe and convenient, material is not easy to be polluted.

Contact Us

- Jiangsu Jinling Drying Technology Co., Ltd.

- Contact nameBarney Wang Chat Now

- Phone86-0519-89893308

- AddressSanhekou Industry Park, Zhenglu Town, Changzhou City, Jiangsu Province, China, Changzhou, Jiangsu

Product Categories

| Mixer | vibration sieve | successful drying technique | steriliztion |

| Sludge Dryer | Rocovery Tower | presser | pelletizer |

| New Products | coater | lifter | incinerator |

| Grinder | Granulator | Furnace | Filter |

| feeder | Drier |

New Products

-

QZL ball granulator

-

QZL pan granulator

-

QZL Pelletizer

-

GZL High Efficiency Extruding Granulator

-

XL Series Extruding Granulating Machine/Pelletizer machine

-

QZL pelletizer

-

QZL pelleting machine

-

QZL pelleting equipment

-

QZL pelleter

-

QZL Vitamin pelletizer

-

QZL pesticide pelletizer

-

QZL phosphate pelletizer

Popular Searches

- Tube Bundle Dryer

- Fluid Bed Dryer

- Dryer Equipment

- Spray Drying Equipment

- vacuum dryer

- Plate Drying Machine

- industrial dryer

- Rotary Drum Dryer

- Cross Joint Shaft

- rotary dryer

- drum dryer

- Vacuum Drying Equipment

- Rotary Drying Equipment

- Dryer Oven

- Spray Dryer

- Rotary Dryer Machine

- Industrial Rotary Dryer

- Rotary Drying Machine

- hopper dryer

- Hopper Drying Machine

- Freeze Dryer

- Industrial Centrifugal Dryer

- cowpea seed

- blood gas machine

- Drier Machine

- lab spray dryer

- Drier Equipment

- air tunnel

- air drying

- mineral dryer

Recommended Products

- Yosion Technology YH-9423A Drying Oven;Industrial Oven;Trolley Oven

- Peptide white powder spray dryer Stainless steel plant protein spray drying equipment

- Yosion Technology YH-D2000T Drying Oven;Industrial Oven;Trolley Oven

- Yosion Technology YH-9623A Drying Oven;Industrial Oven;Sample Preparation Equipment

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- [Explosion-Proof Design] [80-120°C VFD Control] Biomass Vacuum Dryer for Bamboo Powder/Sugarcane Residue [Shandong Manufacturer]

- .[Energy Efficiency Certified] [24KW Motor/90KG Fuel] Vacuum Dryer for Wood Chips/Straw Drying [Jinan Hengyuruntai Supplier]

- Freeze Dryer

- Vacuum freeze dryer

Find Similar Products By Category

- Manufacturing & Processing Machinery > Chemical Equipment & Machinery > Chemical Drying Equipment

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Barney Wang

Hi there! Welcome to my shop. Let me know if you have any questions.

Barney Wang

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile